A Tale of the Nakamoto Family's Passion for their Mountains and Forests

Martin gottschlich

The Nakamoto Family's History and Philosophy

How did nakamoto forestry grow to the biggest manufacturer of yakisugi globally? and what is the companies' deep belief in sustainable forest management about?

Hailing from the lush forests of Yoshiwa, nestled in the mountainous region of western Japan, where the prefectures of Shimane, Hiroshima, and Yamaguchi converge, the Nakamoto family has a storied history deeply intertwined with the timber trade.

Their first records of involvement in the lumber business date back to the Taisho era (1912-1926), a time when Yoshiwa thrived in the forestry industry. Back then, they ventured into cutting chestnut and oak logs, using them as railway ties destined for Hiroshima. Initially, the wood business prospered, but misfortune struck in the late 1920s when a devastating typhoon swept away the 6,000 ties intended for shipment. Consequently, the enterprise suffered a severe blow and eventually filed for bankruptcy around 1931, further exacerbated by the harsh economic climate of the Showa Depression.

Isamu expands Nakamoto family timber business

Enter Isamu Nakamoto, the eldest son of the family, who underwent training at a wood shop in Yokogawa, Hiroshima. He possessed an extraordinary knack for assessing wood volume and transportation costs with a mere glance at the forest, eliminating the need for time-consuming surveys. In May 1935, Isamu returned to Yoshiwa, ready to take the reins of the family business.

With the determination to revive the enterprise, he established a mobile sawmill known as “Nakamoto Zaimoku-Ten” (Nakamoto Timber Store), transporting their sawing machinery to logging sites in the mountains and processing the wood on-site. This innovative approach laid the groundwork for a thriving business, and they later moved operations to Yokogawa in 1939, expanding into wood sales. Nakamoto astutely adapted to market fluctuations, stockpiling products during the spring and summer when prices were low and selling them in winter when demand exceeded supply, thus ensuring rapid growth. Isamu acquired a truck for transportation, traversing the distance between Hiroshima and Shimane on his trusty motorcycle.

Pre- and post-war challenging times for Nakamoto family

The outbreak of the Second Sino-Japanese War in 1937 and the subsequent war economy gradually tightened its grip on Japan. In 1941, the Timber Control Ordinance was enforced, restricting the free operation of the wood and manufacturing industries. However, Nakamoto Zaimoku-ten persisted, albeit with limitations, until 1943 when it was forced to temporarily close its doors.

Post the Pacific War’s conclusion on August 1, 1945, Isamu Nakamoto immediately set to rebuilding the business, resurrecting the mobile sawmill in Yoshiwa. The aftermath of war had left Hiroshima and other major cities in the prefecture devastated, resulting in a pressing demand for wood to aid reconstruction. Toshio, Isamu’s eldest son, joined the Nakamoto family business in the summer of 1947, upon completing his schooling, contributing his efforts to the cause.

Toshio begins reforestation and expands forest stands

Toshio Nakamoto spent the next four years toiling diligently in the Yoshiwa sawmill, and it was during this period that he serendipitously encountered the Hachiro-Sugi., a local cypress species. Responding to the housing shortage, the Japanese government initiated nationwide reforestation efforts, distributing seeds throughout Yoshiwa village.

Toshio received a truckload of seedlings and promptly planted them temporarily in a field behind his house. However, this initial attempt at reforestation proved unsuccessful when it became evident that these seedlings were unsuitable for forestry purposes.

Undeterred, Toshio immersed himself in research, stumbling upon Dr. Kentaro Nakamura’s book “Introduction to Forest Growing.” This comprehensive read became his lifelong companion, as he autodidactically acquired a profound understanding of forestry. Determined to persevere, Toshio began planting native Sugi trees, specifically Hachirou-Sugi, using cuttings.

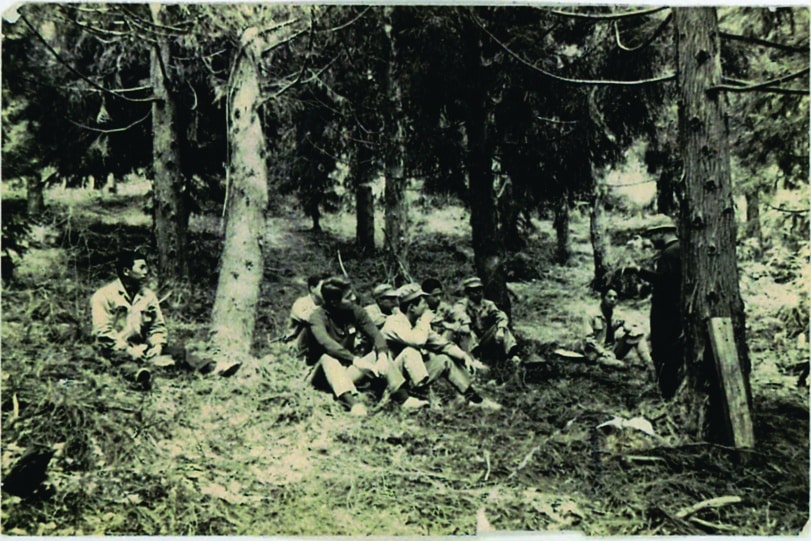

During rainy season, he ventured into the forest, returning with a collection of cypress cones from which he managed to obtain around 130 cuttings. These cuttings were inserted into a potato field and rooted successfully by autumn. The following spring, 105 cuttings were planted in the Oigahara mountain forest, which he owned. With each subsequent learning experience, Toshio soon inserted 250 larger saplings directly into the remnants of grazing land, constituting the first significant plantations in the company’s history.

Isamu held the belief that “the task of the wood industry is to purchase trees planted by others and process them further,” lacking the notion of planting trees for their own use. Until then, most forestry workers, including Isamu, searched for trees in the mountains required for sawmills, outsourcing the felling process. Seldom did they engage in tree planting themselves.

Toshio’s innovative shift in perspective set the stage for Nakamoto’s present endeavors and their ambitious reforestation project in New Zealand under Wood One. In 1949, Toshio reached the age of 20.

Leveraging his ingenuity, Toshio devised a method for collecting Sugi cones from natural forests and cultivating them intensively in nurseries. He then set the ambitious goal of planting 1,000 hectares of forest, initiating a large-scale reforestation effort.

The Nakamoto family company planted approximately 30 hectares of trees per year, and at the height of their ambition, they were planting up to 150,000 saplings annually under the motto “plant, plant, plant, and become Japan’s best forestry company.”

Amidst the rigorous work at his father’s sawmill, Toshio continued planting trees. However, with the centralization of the company’s operations away from Yoshiwa, the challenge of managing the mountains and forests under their jurisdiction arose.

Founding and Development of Nakamoto Zourin

To ensure the continuity of Nakamoto family forestry operations in an appropriate manner, the forestry division was spun off in July 1959, becoming an independent company called Nakamoto Zourin Co., Ltd. Yoshinori Nishigaki, a forest consultant initially hired by the local office of the Hiroshima Prefecture Forestry Authority (later appointed Director and General Manager), assumed responsibility for forest management and cultivation. Nakamoto Zourin was founded with a capital of 2 million yen, with Isamu Nakamoto as president and Toshio Nakamoto as managing director.

Initially, the company managed their forests, amounting to about 300 hectares, as diversified plantations. Subsequently, they incorporated management contracts for forests not owned by the family, while also embarking on efforts to increase the number of forests through reforestation.

At the peak, the Nakamoto family was planting 50-65 hectares of trees per year, with the total number of planted trees surpassing one million by November 1966.

During this era, Japanese policy emphasized reforestation by cutting down natural deciduous forests and planting cedars, cypresses, and other trees. Early maturing varieties were predominantly planted to address the prolonged timber shortage since the middle of the war. However, it would still take a minimum of 20-30 years for the planted trees to become a commercial product. Nakamoto Zourin was the exception, recognizing that producing high-quality wood would take longer than the standard at the time, at least 50 years. To ensure operational sustainability during this period, the company engaged in other activities beyond reforestation.

In April 1963, the company was entrusted with the raw wood business by the sister company Nakamoto Ringyou. Consequently, they began producing and selling roundwood from domestic wood. During this time, the company also installed a chipper and silo at the end of the flooring production process for Nakamoto Ringyou, leading to the production of wood briquettes.

Successive specialized facilities were established, starting with a wood briquette production facility in Kushido in 1966, followed by an interior wood specialty chip plant in Kurisu in 1967, and a second briquette plant in Shimohira in 1968. The profits from these projects were primarily allocated to creating, maintaining, and managing the Nakamoto forests.

By the early 1970s, the reforested area exceeded 1,000 hectares, and forest roads and trails were constructed within the reforested forests. Nakamoto’s reforestation project had garnered recognition, transforming Nakamoto family and Nakamoto Zourin into one of the leading forestry companies in Hiroshima Prefecture.

Establishing a Foothold in the Indoor and Outdoor Building Material Sector

Nakamoto Zourin’s main products today are solid wood products for interior and exterior use, but since 1975 the company has also been active in the sawn wood business. The production and sale of Yakisugi from the company’s own wood stocks began in 1979.

Nakamoto produces Yakisugi according to old Japanese tradition, which is particularly deep-rooted in western Japan along the coastal regions around the Inland Sea and in Hiroshima Prefecture, among other places.

Nakamoto Zourin is a pioneer in the Yakisugi industry when it comes to further development through the use of the latest technologies, for example in innovative coatings, and today holds the largest share of the domestic market.

Our constant efforts for quality, our local environment, and our focus on sustainable operations increasingly gained recognition in the industry. Subsequently, in November 1989, the company was awarded the “Emperor’s Cup” in the forestry category at the Festival of Agriculture, Forestry and Fisheries.

This award also acknowledged the company’s commitment to the local community, such as providing stable employment opportunities in the region through forestry and natural resources. It stands as one of the most significant milestones in the company’s history.

Today, Nakamoto Zourin focuses on producing high-quality solid wood products for both indoor and outdoor applications, especially Yakisugi, a traditional Japanese method of wood finishing. Nakamoto family controls the entire value chain from forestry to distribution and has emerged as a pioneer in the Yakisugi industry.

EU (English)

EU (English) DE (Deutsch)

DE (Deutsch) FR (Français)

FR (Français) UK (English)

UK (English) US Website

US Website